|

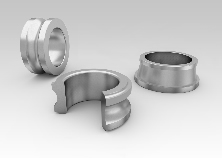

Demagnetizers for bearing components:

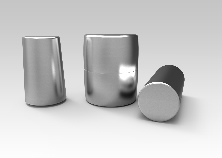

Demagnetizers for assembled bearings:

During the grinding process, the bearing components are held in place by magnetic chucks that provide an optimal grip, essential for the machining of the component. Once the grinding is complete, the bearing components are detached from the magnetic chucks thanks to an inversion of the polarity, which causes a first slight demagnetization. In this phase of the process, depending on the material, the strenght of the magnetic field of the clamps, the orientation of said clamps, a magnetism usually between 10 and 120 A/cm (12.5 and 150 Gauss) remains. Depending on the dimension of the parts, different residual magnetism values are required: minimum values for small components and greater values as the sizes increase. The values required are usually between 2 – 12 A/cm (2.5 – 15 Gauss). The main causes of magnetization of bearing components are:

The main causes of magnetization of assembled bearings are:

To get the best demagnetization result it is essential to first demagnetize the components separately (inner ring, outer ring, rollers, cages and seals) and then when necessary, the assembled bearing. All the components of the bearing and the bearing itself must be demagnetized at excellent values, since high residual magnetism is the cause of many problems. During the production process: the residual magnetism makes a quality washing impossible. Direct consequences on the finished product:

Bearing components or assembled bearings that have not been demagnetized properly have quality characteristics that are much lower than bearing that has been demagnetized at a minimum residual magnetism value. The demagnetizers available for bearing components or assembled bearings are different for each other depending on part dimensions and transfer system. Several demagnetizing solutions are available: in line demagnetizers installed in flexible conveyor chains, demagnetizers for rolling channels, demagnetizing units with integrated conveyor belt or compact conveyor belt. Demagnetizers installed in robotized cells and automated processes, manual and off line demagnetizers. |

|

| Your demagnetization requirements |

||