|

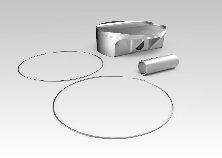

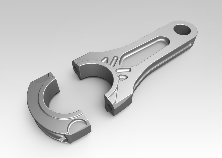

In addition to the high degree of demagnetization, the automotive industry requires a high degree of reliability, High productivity, system flexibility to be modified and reused for different components, ease of use and minimum maintenance. Check the characteristics and the performances of the demagnetizers > The demagnetizers installed in plants of automotive and engine components can be very different from one another, depending on the specific application. We have several optimised solutions adjustable to the production process depending on: the part geometry, the part transfer system (for single parts or parts placed inside washing of transport baskets), in line or manual off line processes. In accordance with the specific requirements of the customers we have developed demagnetizers for: injectors, injector components, valves, con rods, cam shafts, piston rings, piston pin, fuel rail, flywheels, o rings, wheel hubs, shafts, pump bodies, pins, rings and bearings, wheel gears, wheel housings, cylindrical gears and tapered gears, geared shafts, cylindrical crowns, synchroniser components, clutch assemblies, clutch shafts, hoses, clutch cones, hubs, sprocket wheels and many other parts. Holding with magnetic chucks, lathing, magnetoscopic checking, handling with magnetic lifter, are some of the most frequent causes of the magnetization of parts. Unable to wash, handicaps and slowing down during the productive process, early wear and limited life of the components, are some of the serious consequences of the magnetism of the parts. Verify of the causes and consequences of the magnetism > During the production process, high quality demagnetization ensures the optimal washing of the part. Where the washing systems are equal, the better is the demagnetization quality, the better is the quality and the final result of the washing. The magnetism of the parts added to the machining involved, impedes the correct transfer of the parts that might stick to the tools or to other metal parts of the machine, causing machine downtimes and unjustified costs. A demagnetized component sensibly contributes to the overall quality of the finished product. Highly critical components, subject to high work stress where duration and reliability are required must be subjected to an excellent demagnetization. Engine components, transmission parts, not correctly demagnetized wear out easily thereby reducing the duration of the parts themselves. |

|

| Your demagnetization requirements |

||