|

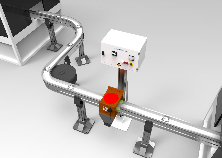

The electronic impulse demagnetizers standard “D-F”, “D-R” and “D-B” series, have been designed to be installed into flexible conveyor chains such as Flexlink, Rotzinger and Bosch types, for the demagnetization of the single part. It is possible to adjust and install these demagnetizers in other flexible chains types and models. For a correct evaluation of the demagnetizing coils installation, please send us:

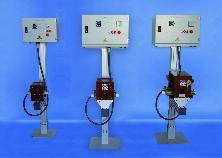

The Demagnetizers consist of an electronic control cabinet with support and a separate demagnetization coil. Depending on the customer needs, demagnetizers can be supplied with or without support. Process Description: The parts are transferred from the line one at a time, inside the demagnetization coil. When the part is in the middle of the coil, the demagnetization impulse is imparted without it being necessary to stop the part and without any magnetic retention. Various electronic control units and coils are available according to the sizes of the parts. Characteristics and Advantages:

Options:

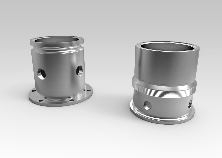

Applications:

Technical data required for a quote:

|

|

| Download the pdf catalogue |

Ask for a quotation complete the form |

|