|

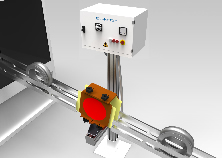

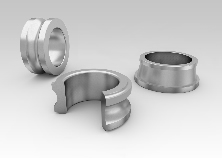

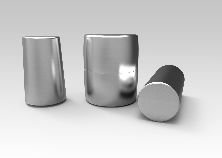

Demagnetizers in line, installed in rolling channels for the demagnetization of the single part. The electronic impulse demagnetizers D-V series, in line for rolling channels, demagnetize round metal parts: rings, rollers and cylinders. Usually installed after the grinding machine, when the part rolling slowly by gravity is in the centre of the coil, the impulse demagnetization is released without the need of stopping the part. For medium-sized parts, the demagnetization coil is fitted with a stop device for stopping in the centre of the coil. This demagnetizer is only indicated for small and medium-sized parts. Characteristics and Advantages:

Technical data required for a quote:

Options:

Applications:

|

|

| Download the pdf catalogue |

Ask for a quotation complete the form |

|